Deposition Tools

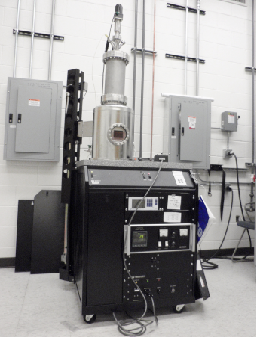

This R&D Atomic Layer Deposition system can provide atomic layer-by-layer growth of ultra thin films. It is a computer controlled rack-sized system with a viscous flow ALD reactor, an enclosed design accommodating a large number of reactant inputs, and can load up to 8” substrates, with uniform heating to 500°C. It is currently used to deposit Al2O3 films. By changing the precursors, other films can be deposited.

The Dimatix DMP-2831 is a flat substrate, xyz stage, “ink jet” deposition system with low cost, user-fillable piezo-based ink jet print cartridges. It has built-in drop jetting observation system, fiducial camera for substrate alignment and measurement. It can achieve variable jetting resolution and pattern creation PC-controlled with Graphical User Interface (GUI) application software and is capable of jetting a wide range of fluids.

This system can be used to print organic circuit for biosensing, solar cell, displacement, cell growth applications in the cleanroom. It can also be used to print micro-electrodes for biological applications.

The PVD 75 is versatile system that can be used for a variety of thin film deposition applications. The Electron beam Evaporation has the following features:

- Telemark 4 Pocket E-Gun

- 5.5 kW Power Supply

- Source Shutter

It is used mainly for metal deposition, such as Al, Cu, Ti, etc (no Au or Ag is allowed).

Kurt J. Lesker Company’s PVD 75 is a customizable evaporation system. The magnetron sputtering module installed in the following instrument is used to deposit oxide layers (SiO2, TiO2, and ZnO). Argon plasma is generated with a radio frequency (RF) source. The resulting ions bombard oxide targets ejecting atomic oxides, which are deposited onto the desired substrate.

A Thermonics thermal evaporator allows thin film metal deposition. Inside the turbine pumped vacuum chamber, dual sources provide for multilayer deposition of chromium, gold, or silver. The system is custom designed with a substrate heater (up to 1000°C) on a rotatory stage.